Stainless steel pipe is a common type of pipe in engineering, and the two most common materials are 201 and 304. It has the irreplaceable advantages of other pipes. It will be used more and more in engineering, its use will become more and more popular, and its prospects are promising.

In some cases, stainless steel pipes have advantages, especially thin-walled stainless steel pipes with a wall thickness of only 0.6 to 1.2 mm. They are safe in high-quality drinking water systems, hot water systems, and water supply systems that put safety and hygiene first. Reliable, hygienic, environmentally friendly, economical and applicable. It has been proven by domestic and foreign engineering practices that it is one of the new, energy-saving and environmentally friendly pipes with the best comprehensive performance in water supply systems. The following is a detailed introduction to stainless steel pipes.

Summary of stainless steel pipe types and uses

1. Stainless steel decorative pipe

- Material: mainly 201 and 304, with a small amount of 301 and 316

- Purpose: Mainly used for decoration projects such as stairs, doors, windows and guardrails, and some products with lower requirements for piping

- Features: bright surface, brushed or frosted, poor alignment

2. Stainless steel product pipes

Material: mainly 201, 304, 316

Usage: bathroom furniture, product piping, fluid pipes, etc.

Features: Strict requirements for positive and negative specifications, surface brightness and workmanship, etc., and there will be requirements for pipe bending, expansion and contraction, etc.

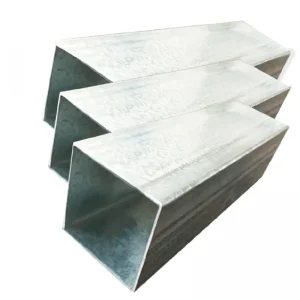

3. Stainless steel special-shaped pipes

Special-shaped pipes generally adopt the method of secondary pressure forming of round pipes when the quantity is small (except for grooved pipes). Large quantities can be customized for production. Due to different specifications, molds are sometimes lacking, and corresponding mold costs may need to be borne.

- Elliptical tube: regular elliptical tube, flat elliptical tube

- Grooved tubes: round tubes, square tubes, rectangular tubes, oval tubes, etc. can all be grooved. They are generally used for glass in guardrail frames.

- Others: triangle, handrail, arch, fan shape, door frame tube, etc.

4. Stainless steel pattern pipe

The emergence of patterned pipes has changed the single appearance of traditional stainless steel pipes, which is refreshing. Recently, many pipe factories have launched patterned pipe projects.

- Ordinary embossing: traditional round tube embossed with gourd pattern section by section

- European embossing: Patterns such as shapes, auspicious clouds, money, etc. are embossed on the surface of the pipe.

5. Colored stainless steel tubes

Coating a layer of color on the surface of stainless steel pipes, any material specification is acceptable. The processing cost will be increased based on the square meter of the pipe. In the past, the color plating was always less than four meters, but now gold, rose gold, and black titanium can be plated up to 6 meters. , colored tubes need to reduce the probability of welding and use linking parts.

6. Stainless steel composite pipe

- Stainless steel composite pipe: In the past two years, composite pipes with surface 304 and inner layer 201 appeared. Now after the price of 304 has dropped, the composite pipe has been reduced.

- Carbon steel composite pipe: surface 201 or 304, internal carbon steel, surface thickness less than 1.0, generally used in highway guardrail projects.

Stainless steel industrial pipes

Industrial pipes also include welded pipes and seamless pipes, which are mainly used in engineering structures, various types of pipelines, etc.

What are the classifications of stainless steel pipes?

1. Stainless steel pipes are classified according to material

They are divided into ordinary carbon steel pipes, high-quality carbon structural steel pipes, alloy structural pipes, alloy steel pipes, bearing steel pipes, stainless steel pipes, as well as bimetallic composite pipes, plated and coated pipes to save precious metals and meet special requirements. Many types of stainless steel pipes have different uses, technical requirements, and production methods.

2. Classification by production method

Stainless steel pipes are divided into two categories: seamless pipes and welded pipes according to production methods. Seamless steel pipes can be divided into hot-rolled pipes, cold-rolled pipes, cold-drawn pipes, and extruded pipes. Cold-drawn and cold-rolled pipes are the secondary processes of steel pipes. Processing; welded pipes are divided into straight-seam welded pipes and spiral welded pipes.

3. Classification according to cross-sectional shape

Stainless steel pipes can be divided into round pipes and special-shaped pipes according to their cross-sectional shapes. Special-shaped tubes include rectangular tubes, rhombus tubes, oval tubes, hexagonal tubes, octagonal tubes, and various asymmetrical cross-section tubes. Special-shaped tubes are widely used in various structural parts, tools, and mechanical parts.

4. Classification according to pipe end shape

Stainless steel pipes can be divided into plain pipes and threaded pipes (threaded steel pipes) according to the condition of the pipe end. Threaded pipes can be divided into ordinary threaded pipes (pipes for low-pressure transportation of water, gas, etc., which are connected by ordinary cylindrical or conical pipe threads) and special threaded pipes (pipes for petroleum and geological drilling. For important threaded pipes, use Special thread connection), for some special pipes, in order to compensate for the influence of threads on the strength of the pipe end, the pipe end is usually thickened (internal thickening, external thickening or internal and external thickening) before threading.

5. Classification by use

According to the use, it can be divided into oil well pipes (casing, oil pipes and drill pipes, etc.), pipeline pipes, boiler pipes, mechanical structural pipes, hydraulic support pipes, gas cylinder pipes, geological pipes, chemical pipes (high-pressure fertilizer pipes, petroleum cracking pipes) ) and ship pipes, etc.

Stainless steel pipe is a kind of hollow long round steel, which is mainly widely used in industrial transportation pipelines and mechanical structural components such as petroleum, chemical industry, medical treatment, food, light industry, mechanical instrumentation, etc. In addition, when the bending and torsional strength are the same, the weight is lighter, so it is also widely used in manufacturing mechanical parts and engineering.