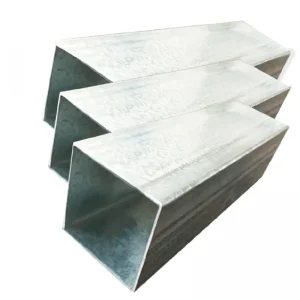

Steel plate is a flat steel material, mainly made of steel, and has a flat or rectangular shape. Steel plates are made by pouring molten steel, cooling it, and then pressing it. Steel plates have the characteristics of high strength, wear resistance and corrosion resistance, so they are widely used in many fields such as construction, aerospace, automobile manufacturing, machinery manufacturing, civil appliances, and transportation. Steel plates can be divided into many types according to different standards and uses, such as ordinary steel, high-quality steel, alloy steel, spring steel, stainless steel, tool steel, heat-resistant steel, bearing steel, silicon steel and Industrial pure iron sheets, etc. In addition, steel plates can also be divided into galvanized sheets, tin-plated sheets, lead-plated sheets and plastic composite steel sheets according to surface treatment. Steel plates come in different thicknesses and widths, for example, thin steel plates are usually less than 0.5 mm thick, while medium and thick plates are between 4 and 60 mm thick.

Classification of steel plates (including steel strips):

- Classification by thickness: (1) thin plate (2) medium plate (3) thick plate (4) extra thick plate

- Classification by production method: (1) Hot-rolled steel plate (2) Cold-rolled steel plate

- Classification according to surface characteristics: (1) Galvanized sheet (hot-dip galvanized sheet, electro-galvanized sheet) (2) Tin-plated sheet (3) Composite steel sheet (4) Color-coated steel sheet

- Classification by use: (1) Bridge steel plate (2) Boiler steel plate (3) Shipbuilding steel plate (4) Armor steel plate (5) Automobile steel plate (6) Roofing steel plate (7) Structural steel plate (8) Electrical steel plate (silicon steel sheet) (9) Spring steel plate (10) Others

Hot rolling:

Pickled coils Hot rolled coils Structural steel plates Automobile steel plates Shipbuilding steel plates Bridge steel plates Boiler steel plates Container steel plates Corrosion-resistant plates Replacing cold with heat Baosteel wide and thick plates Fire-resistant and weather-resistant steel

Cold rolling:

Hard-rolled coil Cold-rolled coil Electro-galvanized sheet Hot-dip galvanized sheet Galvalume-zinc sheet Color-coated sheet coil Tin-coated sheet coil Baosteel Electrical Steel Composite Steel Plate Cold-rolled steel strip Aluminized sheet GB Hot-dip galvanized Galvalume zinc color coated color card Use of GB tinned WISCO silicon steel

Boiled steel plate and killed steel plate:

- Boiled steel plate is a steel plate made of hot-rolled ordinary carbon structural steel and boiled steel. Boiling steel is a kind of steel with incomplete deoxidation. Only a certain amount of weak deoxidizer is used to deoxidize the molten steel. The molten steel contains high oxygen. When the molten steel is injected into the steel ingot mold, the carbon-oxygen reaction produces a large amount of gas, causing the molten steel to boil. , from which boiling steel gets its name. The carbon content of boiling steel is low. Since ferrosilicon deoxidation is not required, the silicon content in the steel is also low (Si<0.07%). The outer layer of boiling steel is crystallized under the conditions of violent stirring of liquid steel caused by boiling. Therefore, the surface layer is pure and dense, with good surface quality, good plasticity and stamping performance, and no large concentrated shrinkage holes or cut ends. Less, high yield rate, simple boiling steel production process, less ferroalloy consumption, and low steel cost. Boiled steel plates are widely used in the manufacture of various stamping parts, construction and engineering structures and some less important machine structural parts. However, there are more impurities in the core of boiling steel, the segregation is more serious, the structure is not dense, and the mechanical properties are uneven. At the same time, due to the high gas content in steel, the toughness is low, the cold brittleness and aging sensitivity are high, and the welding performance is also poor. Therefore, boiled steel plates are not suitable for manufacturing welded structures and other important structures that bear impact loads and work under low temperature conditions.

- Killed steel plate is a steel plate made by hot rolling of ordinary carbon structural steel and killed steel. Killed steel is completely deoxidized steel. The molten steel is fully deoxidized with ferromanganese, ferrosilicon and aluminum before pouring. The oxygen content of the molten steel is low (generally 0.002-0.003%), and the molten steel is relatively calm in the ingot mold. There is no boiling phenomenon, hence the name of killed steel. Under normal operating conditions, there are no bubbles in the killed steel, and the structure is uniform and dense; due to the low oxygen content, there are fewer oxide inclusions in the steel, higher purity, and less cold brittleness and aging tendency; at the same time, the segregation of the killed steel is small, The performance is relatively uniform and the quality is high. The disadvantages of killed steel are concentrated shrinkage cavities, low yield, and high price. Therefore, killed steel is mainly used for components that withstand impact at low temperatures, welded structures and other components that require higher strength.

Low alloy steel plates are both killed steel and semi-killed steel plates. Due to its high strength and superior performance, it can save a lot of steel and reduce the weight of the structure, and its application has become more and more widespread.

High-quality carbon structural steel plates:

High-quality carbon structural steel is carbon steel with a carbon content of less than 0.8%. This kind of steel contains less sulfur, phosphorus and non-metallic inclusions than carbon structural steel, and has better mechanical properties.

High-quality carbon structural steel can be divided into three categories according to different carbon contents: low carbon steel (C ≤ 0.25%), medium carbon steel (C 0.25-0.6%) and high carbon steel (C > 0.6%).

High-quality carbon structural steel is divided into two groups according to its manganese content: normal manganese content (manganese content 0.25%-0.8%) and higher manganese content (manganese content 0.70%-1.20%). The latter has better mechanical properties. performance and processing properties.

- High-quality carbon structural steel hot-rolled thin steel plates and steel strips High-quality carbon structural steel hot-rolled thin steel plates and steel strips are used in the automobile, aviation industry and other sectors. The steel grades are boiling steel: 08F, 10F, 15F; killed steel: 08, 08AL, 10, 15, 20, 25, 30, 35, 40, 45, 50. 25 and below are low carbon steel plates, 30 and below Above 30 is medium carbon steel plate.

- High-quality carbon structural steel hot-rolled thick steel plates and wide steel strips High-quality carbon structural steel hot-rolled thick steel plates and wide steel strips are used for various mechanical structural parts. The steel grades are low carbon steel including: 05F, 08F, 08, 10F, 10, 15F, 15, 20F, 20, 25, 20Mn, 25Mn, etc.; medium carbon steel include: 30, 35, 40, 45, 50, 55, 60, 30Mn, 40Mn, 50Mn, 60Mn, etc.; high carbon steel includes: 65, 70, 65Mn, etc.

6. Special structural steel plates:

- Steel plate for pressure vessels: It is represented by a capital R at the end of the grade. The grade can be expressed by the yield point or the carbon content or alloying elements. For example: Q345R, Q345 is the yield point. Another example: 20R, 16MnR, 15MnVR, 15MnVNR, 8MnMoNbR, MnNiMoNbR, 15CrMoR, etc. are all expressed by carbon content or alloying elements.

- Steel plates for welded gas cylinders: Use capital letters HP at the end of the grade. The grade can be expressed by yield point, such as: Q295HP, Q345HP; it can also be expressed by containing alloy elements, such as: 16MnREHP.

- Steel plates for boilers: Use a lowercase g at the end of the grade. The grade can be expressed by the yield point, such as: Q390g; it can also be expressed by the carbon content or alloying elements, such as 20g, 22Mng, 15CrMog, 16Mng, 19Mng, 13MnNiCrMoNbg, 12Cr1MoVg, etc.

- Steel plates for bridges: Use a lowercase q at the end of the grade, such as Q420q, 16Mnq, 14MnNbq, etc.

- Steel plates for automobile girder: Use capital L at the end of the grade, such as 09MnREL, 06TiL, 08TiL, 10TiL, 09SiVL, 16MnL, 16MnREL, etc.