The steel wire rope is a spiral steel wire bundle that is twisted together according to certain rules with steel wires that meet the requirements of mechanical properties and geometric dimensions. The steel wire rope is composed of steel wires, rope cores and grease. A steel wire rope is first twisted into strands from multiple layers of steel wire, and then a certain number of strands are twisted into a spiral rope with the rope core as the center. In material handling machinery, it is used for lifting, pulling, tightening and carrying. The steel wire rope has high strength, light weight, stable operation, not easy to break suddenly, and reliable operation.

Steel wire rope composition

1. steel wire

The steel wire rope needs to withstand alternating loads during use. Its performance is mainly determined by the mechanical properties of the steel wire, the surface condition of the steel wire and the structure of the steel wire rope. Steel wire materials include carbon steel or alloy steel, which are made by cold drawing or cold rolling. The steel wire cross-sections are round or special-shaped (T-type, S-type, Z-type). Special-shaped cross-section steel wires are mainly used for the production of sealed steel wire ropes and have relatively high performance. High tensile strength and toughness, and suitable surface treatment of steel wires to meet the needs of different environmental conditions.

2. rope core

The main function of the rope core is to support the steel wire rope to achieve a stable cross-sectional structure. The rope core includes steel core and fiber core. The fiber core includes natural fiber core and synthetic fiber core. Natural fiber core such as sisal, jute, cotton thread, etc., and synthetic fiber core includes polyethylene and polypropylene filament, etc. The natural fiber core can store more grease, lubricate the wire rope and extend the service life of the wire rope.

3. grease

Grease is sprayed during the twisting process of the steel wire rope. Its main functions are twofold. First, it lubricates the steel wire rope and slows down the wear on the surface of the steel wire. Second, the grease can isolate the surface of the steel wire from oxygen in the air, causing oxidation and corrosion of the steel wire rope. Play an inhibitory role.

Wire rope classification

1. Classification according to material

- Carbon steel wire rope is twisted from high-quality carbon structural steel wire.

- Stainless steel wire rope, made and twisted from stainless steel wire

2. Classification according to surface condition

- Phosphated coated steel wire rope (Chinese patent), referred to as phosphated steel wire rope. The weight of the phosphating film on the rope-making steel wire is 3-60 grams/square meter. After phosphating, the steel wire is not cold drawn before twisting, and the strand rope is directly twisted. , steel core and steel wire rope, the phosphate coating can improve the wear resistance and corrosion resistance of the surface of the rope-making steel wire, and effectively inhibit the occurrence of fretting fatigue. For the phosphating treatment of rope-making steel wires, manganese or zinc-manganese phosphating is preferred. No drawing processing is performed after the phosphating of the steel wires. The phosphated steel wires are used directly to twist the steel wire ropes. The phosphating coating makes the surface of the steel wire more wear-resistant. Moreover, the phosphate film is non-conductive and can simultaneously improve the corrosion resistance of the steel wire. The service life of the phosphated steel wire rope is 2-3 times that of the smooth steel wire rope, and the fatigue resistance of the steel wire rope is greatly improved. [1] Phosphated steel wire rope is not only an ideal substitute for smooth steel wire rope, but also fully capable of replacing imported steel wire rope [2-3].

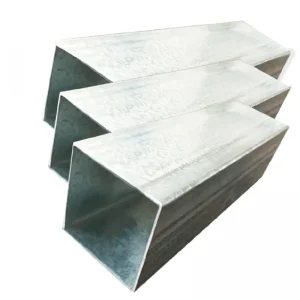

- Galvanized steel wire rope, including hot-dip galvanizing and electro-galvanizing. The protection of the steel wire by the galvanized layer is anode protection. The thicker the galvanized layer, the stronger the anti-corrosion ability.

- Plastic-coated steel wire ropes are coated with a certain thickness of plastic on the outer surface of the steel wire rope or the outer surface of the strand rope, including polyethylene, polypropylene, polyurethane, etc.

- Smooth steel wire rope is a rope-making steel wire obtained by cold drawing of raw materials after heat treatment and surface preparation (note: the phosphating film formed during the pretreatment process gradually falls off due to intense friction with the drawing die during the cold drawing process), and the steel wire is no longer Strands, steel cores and wire ropes are directly twisted after any surface treatment. Production began in 1834 abroad and in China in 1939 by Tianjin No. 1 Steel Wire Rope Factory.

3. Classification according to twisting method

single strand rope

Also known as single-twist rope, it is made of rope-making steel wires twisted around a central wire or hemp core. One or more layers of steel wires can be twisted.

Double twist rope

It is made of double-stranded ropes twisted around a rope core (steel core or fiber core). It can be twisted into one or more layers of steel wire. It is the most widely used type of steel wire rope.

triple twist rope

It is made of double-twisted ropes as strands and twisted around the rope core. It is mainly used for thick-sized steel wire ropes with a diameter of more than 60mm, such as offshore steel wire ropes.

4. Status classification

According to the contact state between adjacent layers of steel wires in the strand, it is divided into three types: point contact, line contact or surface contact.

①Point contact steel wire rope: The diameter of the steel wires in the strand is the same, the twist angles between the steel wires in each layer are the same, and the lay distance is different, so the inner and outer wires cross each other and form a point contact state.

②Line contact steel wire rope: The lay distance of each layer of steel wires in the strand is the same but the twist angle is different. The inner and outer steel wires are in contact with each other on a spiral line, showing a line contact state. Under the same conditions of use, the service life of line contact wire ropes is longer than that of point contact wire ropes.

③ Compaction type steel wire rope, formerly known as surface contact steel wire rope. During the twisting process of the steel wire rope, after forging, drawing, etc., a contact surface is formed between the steel wires, including strand rope compaction, wire rope compaction and double strand compaction, etc. .

④Sealed wire rope: The outer layer is made of special-shaped steel wire, including T-shaped, S-shaped, and Z-shaped cross-section steel wires. It has a smooth surface and good wear resistance. Compared with other types of steel wire ropes of the same diameter, it has greater tensile strength and can It can withstand lateral pressure, but has poor flexibility, complicated processes, and high manufacturing costs. It is often used as load-bearing cables, such as cables on cable cranes and aerial ropeways.

Steel wire rope production process

The production of steel wire rope has three basic processes: drawing, twisting and tying.

1. Brushed

Raw materials: The wire rope drawing mentioned here refers to a process in which the raw materials are pickled, phosphated, shelled, and blanked, during which one or more pulls are performed to change its molecular structure and make it reach the target diameter.

The raw materials include ferrous metals with a diameter of 0.14~10.00mm and non-ferrous metals with a diameter of 0.01~16.00mm.

Pickling: The process of using acid to remove rust and skin on the surface of the raw material of the wire rope. In the wire rope production process, it is also called shelling. It mainly peels off the oxides of the high wires to prevent rust and other impurities from affecting the blanking and damaging the drawing mold.

Phosphating: In layman’s terms, it is a process of immersing materials in a phosphate solution to obtain a water-insoluble phosphate film on the surface. Prevent corrosion to a certain extent.

Blank opening: a hole of a certain shape through the center of various molds for drawing metal wires, round, square, octagonal or other special shapes. When the metal is forced through the die hole, the size and shape change.

Cold drawn wire: If you force ordinary round steel through a hole that is smaller than its diameter, the diameter of the round steel will become smaller and the length will elongate. If you repeat this process, the round steel will become further become smaller. After this plastic deformation occurs, the hardness of the steel will increase and the plasticity will basically disappear. Such steel can be used when plasticity is not required but only strength is required.

Tempering: Because the molecular structure of the steel wire has been destroyed, only tempering can restore the internal structure of the steel wire. In order to facilitate drawing again, it will not break easily and can be drawn to the strength we want. Strength is what we call tensile strength. The strength comes from drawing, not heat treatment. This is the biggest difference between wire rope technology and mechanical processing technology. General strength: 1470N/mm2, 1570N/mm2, 1670N/mm2, 1770N/mm2, 1870N/mm2, 1960N/mm2. The higher the strength, the stronger the tensile force, but the worse the toughness. Therefore, the appropriate strength should be selected when selecting steel wire ropes. You can’t just go to high intensity. High-strength steel wire ropes have strong tensile strength, but are relatively weak in terms of wear resistance and flexibility.

2. twisted strands

Type, structure and use of twisted strands The type, structure, raw materials and production process of the wire rope depend on the use. Generally, steel wire ropes use carbon steel wire with a circular cross-section with a diameter of 0.1~6.0mm. When twisting sealed and semi-sealed steel wire ropes, Z-shaped and other special-shaped steel wires are used. The types of steel wire ropes are divided according to their uses: ropes for suspension bridges and twisted strands for mining, load-bearing ropes for aerial ropeways, traction ropes for transmission devices, ropes for elevators, lashing ropes for bundling and towing cargo, etc. The types of steel wire ropes are increasing and their structures are becoming increasingly complex. In addition to various coated steel wires, stainless steel wires and bimetallic steel wires are also used. In order to ensure the safety and reliability of the use of steel wire ropes, the steel wire ropes are required to have sufficient strength, good flexibility, twisting compactness, pressure resistance, wear resistance, corrosion resistance and fatigue resistance, among which strength is the most important. .

The cross-sectional structure of the wire rope includes point contact round strands, line contact round strands, surface contact round strands, special-shaped strands, single-layer strands that do not rotate, are sealed and flat, etc. Among them, the surface contact round strand steel wire rope is made by drawing the line contact strands through a wire drawing die or a roller die by the traction force of the twisting machine. Through the drawing die, there are two anti-corrosion measures in the cross-section twisted strands before and after deformation of the rope strands: oiling and plating.

Oiling: All wire ropes must be oiled. The fiber core is immersed in oil, which requires the grease to protect the fiber core from rotting and rusting the steel wire, moisturizing the fiber, and lubricating the steel wire rope from the inside. Surface oiling ensures that the surface of all steel wires in the rope strand is evenly coated with a layer of anti-rust lubricating grease. For mine ropes with large friction lifting and mineral water, black oil grease with strong abrasion and water resistance must be coated; for other uses, Apply red oil with strong film-forming properties and good anti-rust properties, and the oil layer is required to be thin so that it can be kept clean during operation.

Coating: galvanized, aluminum plated, nylon coated or plastic, etc. Galvanizing is divided into thin coatings where the steel wires are first plated and then pulled out, and thick coatings where the steel wires are pulled out and then galvanized. The mechanical properties of the thick coatings are lower than those of smooth steel wire ropes and should be used in severely corrosive environments. Aluminized steel wire rope is more corrosion-resistant, wear-resistant, and heat-resistant than galvanized steel wire rope. It is mainly used in fishing trawlers and mines containing H2S. It is produced by plating first and then drawing. There are two types of wire ropes coated with nylon or plastic: coated ropes and coated stranded ropes. The former is used for static cables, and the latter is used for moving cables.

Winding process: Rewind the steel wire reel onto the I-wheel of the twisting machine; you can also roll the steel wire onto the I-wheel directly from the wire drawing machine. Twisting twists steel wire into rope strands. Twisting machines include basket type, shaft and tube type, tubeless type and double twisting machines. This is a schematic diagram of a 12-axis tube twisting machine. 1 is the I-wheel that holds the lower rope strands, 2 is the rotating barrel containing 12 I-wheels filled with steel wires, 3 is the stranded crimping tile, and 4 is The traction wheel, 5, is the take-up wheel of the upper rope strand. When the barrel rotates once, the length of the rope strand drawn out by the traction wheel is the lay length of the strand.

3. close rope

The process of arranging the rope strands in a spiral around the center line of the rope core on a rope closing machine to produce a steel wire rope. The rope closing must be carried out in strict accordance with the regulations on the wire rope manufacturing process. After the rope combining machine is selected, the rope strands should be carefully selected. The specifications, structure, twisting direction (see wire rope twisting method), length, etc. of the strands should meet the requirements of the wire rope manufacturing card. After the strands are selected, install the strand-carrying I-shaped wheel on the I-shaped wheel frame of the rope closing machine. The installation of the I-shaped wheel, the threading method of the strands, the adjustment of the twisting parameters and the twisting operation in the rope closing process are the same as those in the twisting process. Compared with twisted rope, the only difference is in the twisting process. The twisting of steel wire ropes is divided into three types: the twisting of single-twisted steel wire ropes, the twisting of double-twisted steel wire ropes and the twisting of triple-twisted steel wire ropes.

The twisting method and twisting process of single-twisted steel wire ropes are basically the same as those of strands of the same structure. The only difference is that in single-twisted steel wire ropes, the twisting directions of the steel wires in each twisted layer outside the rope core are alternate. If it changes, the twist direction is determined according to the twist direction of the outer steel wire. Sealed steel wire rope is a single-twisted steel wire rope. The twisting method is similar to that of round-strand single-twisted steel wire rope. The difference is that when twisting, it must be ensured that the large surface of the special-shaped steel wire outside the rope core always faces the outer surface of the steel wire rope. The twisting of special-shaped steel wires outside the core of sealed steel wire ropes is generally completed on special equipment.

Double-twisted steel wire ropes are usually made of 2, 3, 4, 6, 7, or 8 strands. It can reach up to 36 strands, has many varieties, and has a complex structure. It is the most widely used steel wire rope. The most commonly used is a double-twisted steel wire rope composed of 6 strands. Medium and fine specifications of double-twisted steel wire ropes can be twisted using a tubular twisting machine. Thick-gauge steel wire ropes, especially co-twisted steel wire ropes (see wire rope twisting method), are twisted using a basket-type rope combining machine. Special-shaped strand wire ropes can be twisted using special equipment, or round strands can be transformed into special-shaped strands on an ordinary rope-making machine and then twisted into wire ropes. Surface contact steel wire ropes can be manufactured by the special-shaped wire rope twisting method or the plastic compression method. The plastic compression method is to subject round strands to drawing or rolling during twisting, causing plastic deformation of the steel wires in the strands, changing the contact state of the steel wires in the strands, and then twisting the strands to make steel wire ropes. The twisting of three-twist steel wire rope is the same as that of double-twist steel wire rope, but the number of twists is increased.

All wire ropes should be twisted so that they are not loose. The tightness of the wire rope is achieved by pre-deforming the twisted strands when closing the rope. Steel wire ropes with metal cores can also be heat treated to obtain non-loose properties. In order to improve the mechanical properties and non-looseness of the wire rope, in addition to pre-deforming the strands when closing the rope, the strand straightening process is also widely used during twisting and closing to eliminate the twisting stress of the wire rope.

There is a wire rope oiling tank between the traction wheel and the take-up device of the rope closing machine to apply oil to the wire rope. After the steel wire rope is oiled, it is evenly wound on the I-wheel of the take-up mechanism through the wiring mechanism. After the twisting is completed, the rope ends of the steel wire ropes are tied tightly with soft steel wires and fixed on the I-shaped wheel disc.